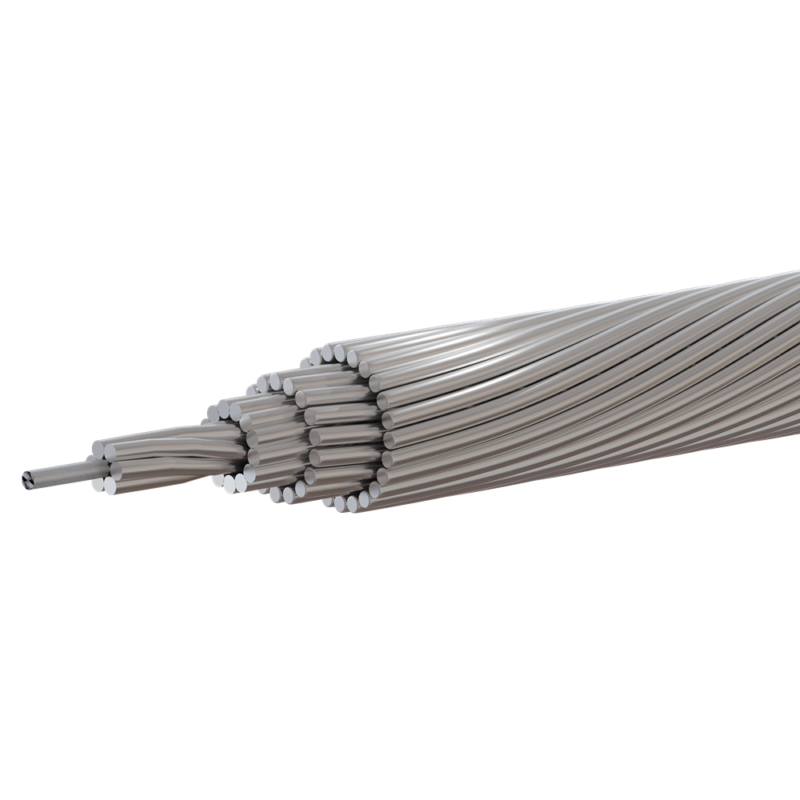

series (Aluminum Alloy 1350 is highly conductive and possesses good ductility, which leads to its use in electronics). These conductors are stranded in one or more layers around a central wire with a circular cross-section. Each layer has 6 more strands than the previous layer. The high flexibility of these conductors allows for an increased number of layers for a specific cross-section. AAC conductors are manufactured in accordance with the requirements of ASTM B230 and ASTM B231 standards.

Stranding: These conductors are generally designed with a number of strands such as 7, 19, 37, 61, and 91.

Class: Class AA is used for bare conductors intended for overhead lines. The lay direction of the outer layer in these conductors is right-hand lay, and it is usually in the opposite direction of the preceding layer.

Features

Low weight in this product means a lower cost per unit length of the conductor, easier handling during installation, and a reduction in complex connections, making these conductors economically viable (or cost-effective

All-aluminum conductors inherently possess high corrosion resistance, a characteristic that is due to the homogeneous structure of these conductors.

Applications

All-Aluminum 1350 conductors (AAC) are used in overhead distribution and transmission lines under conditions where:

The span lengths (distance between utility poles) are short.

High strength and higher temperature tolerance are not critical design parameters compared to ACSS, ACSR, or other conductor types.

The conductor’s current-carrying capacity (ampacity) is the more important factor.