Cored Wires (Cord Wires)

- Cored wires are essentially hollow metal tubes whose interiors are filled with various chemical powders, mineral salts, and combinations of metals.

- Cored wires significantly increase work speed. In the steel industry, cored wires allow faster production, which deeply impacts efficiency and productivity.

- They are also widely used in the casting industry, providing comprehensive control over the accuracy of chemical elements. Precise monitoring, management, and inspection of casting products have brought significant improvements to this industry.

Cored wires are essentially hollow metal tubes whose interiors are filled with various chemical powders, mineral salts, and combinations of metals.

Cored wires significantly increase work speed. In the steel industry, cored wires allow faster production, which deeply impacts efficiency and productivity.

They are also widely used in the casting industry, providing comprehensive control over the accuracy of chemical elements. Precise monitoring, management, and inspection of casting products have brought significant improvements to this industry.

- Cored wires significantly increase work speed. In the steel industry, cored wires allow faster production, which deeply impacts efficiency and productivity.

- They are also widely used in the casting industry, providing comprehensive control over the accuracy of chemical elements. Precise monitoring, management, and inspection of casting products have brought significant improvements to this industry.

قطعا وقتی یک محصول در میان صنایع تولیدی به محبوبیت و جایگاه ویژه ای دست پیدا می کند، حتما دارای قابلیت ها و مزیت های بخصوصی است . این موضوع درخصوص کورد وایر هم صدق می کند . برای آگاهی از اینکه مزایای کورد وایر چیست و چرا استفاده از این محصول تا این اندازه مورد توجه قرار گرفته، در ادامه به لیستی از قابلیت های آن اشاره می کنیم :

- Highly effective in deep deoxidation

- Perform precise and thorough desulfurization

- Reduce weight and increase sphericity of inclusions, helping them float toward the slag phase

- Significantly improve impact properties of newly produced steel

- Minimize the release of harmful substances into the environment

- Ferrosilicon magnesium cored wires perform treatment processes at very low costs

- Reduce labor requirements in casting processes, increasing work speed

- High flexibility

- Long service life

- Cost-effective and reduce melting costs

- Low consumption

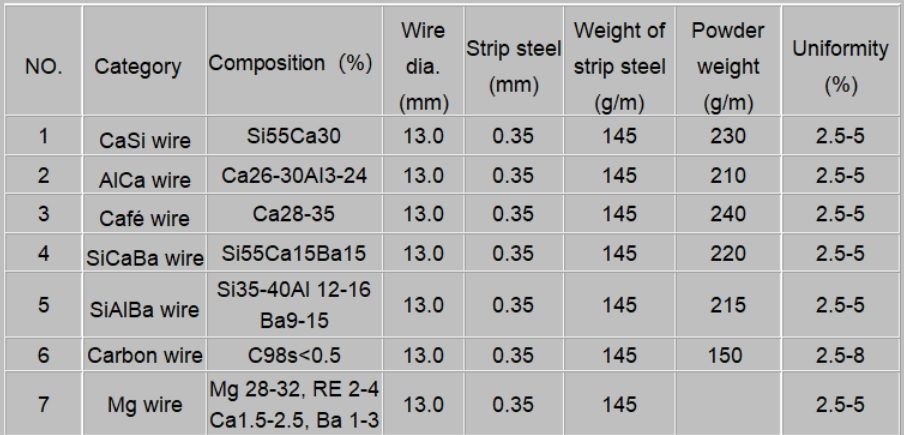

Classification of Cored Wires:

Cored wires are classified based on appearance, physical properties (dimensions, height, weight), materials and composition, tensile strength, chemical composition, slag behavior, and gas conditions. For example,

- some cored wires produced by Sim Rad Sama Company include

Cored wires can also be produced in different grades, depending on the materials and elements used.

Wire diameter

9.5 mm and 13 mm, according to customer requirements

Coil weight

1300–1500 kg, adjustable based on production type

Wall thickness

0.4–1 mm, depending on the sheath used for wire production

Packaging: Horizontal or vertical metal coils

It should be noted that coil weight and packaging type can be customized according to customer requirements and orders.