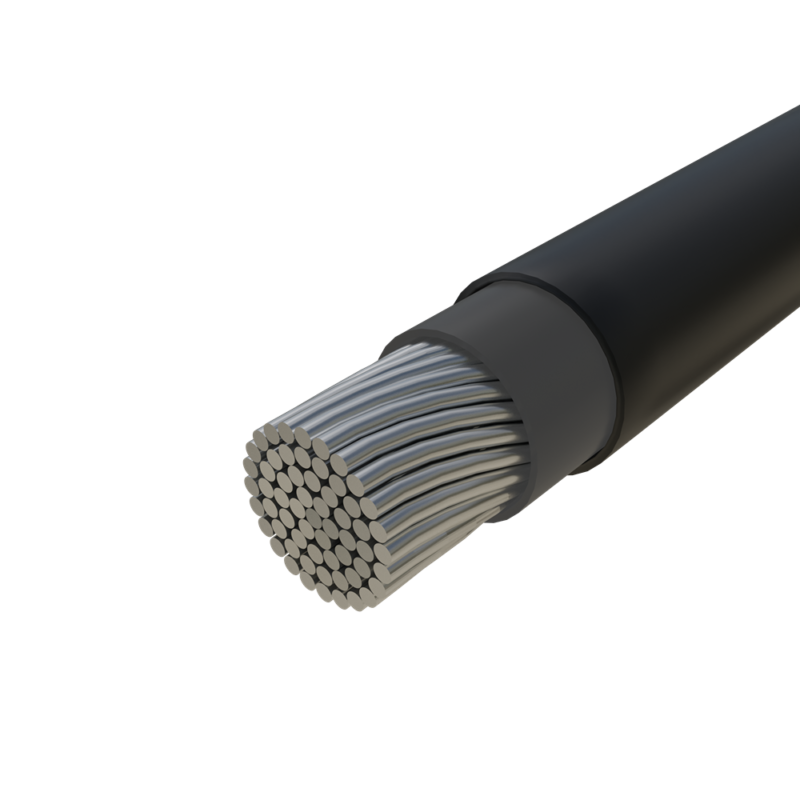

The low voltage single-core power cable with an aluminum conductor is a type of power cable used for transmitting electric current in lighting systems, industrial equipment, and some building wiring. This cable uses a single aluminum core (AAC) as the conductor, which is separated by an insulating layer to prevent interference between different currents.

The insulation of these cables can be made of PVC (NAYY) or XLPE (NA2XY), which prevents moisture and water ingress and increases the cable’s service life. Additionally, a PVC sheath is applied over the cable to protect it from air, water, soil, and other external factors.

Due to features such as good electrical conductivity, high mechanical strength, lower weight compared to steel-core cables, and reasonable cost, this cable is widely used in many applications. It can be installed buried in the ground, inside ducts, on cable trays, or within buildings. In some cases, these cables are produced with a high-strength heat-resistant insulation layer, making them suitable for industrial, electrical, oil, gas, and other sectors.

Because of its lower weight compared to copper cables, the low voltage aluminum conductor cable is sometimes used as a substitute for copper cables. However, due to aluminum’s lower electrical conductivity compared to copper, optimization and proper conductor sizing are important for longer cables with greater distances between endpoints.

Overall, the low voltage power cable with an aluminum conductor is one of the most commonly used types of cables in the electrical industry, valued for its good electrical conductivity, lighter weight compared to copper cables, and versatility in various applications.